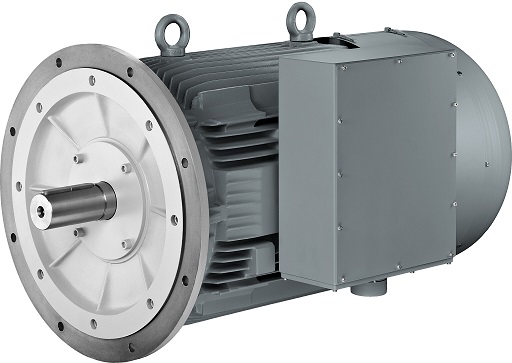

MMR Group TransComfort offers AC motors manufactured by Emod Motoren GmbH.

EMOD Motoren GmbH has been producing motors for 70 years. Each inquiry and motor production are considered individually – together with EMOD designers, we adjust the motor and its technical parameters to the given application and current needs (e.g. in terms of noise reduction or structure volume).

Electric motors, which we have in our basic offer are:

- marine motors:

- for upper and lower decks – standard IP56, IP55 and IP23,

- also in explosion-proof ATEX version (upper deck),

- with possibility of approval of classification societies,

- three-phase motors:

- IP23 – IP55 standard,

- from 0,02 kW to 1700 kW,

- size from 35 to 560,

- wound rotor induction motors,

- water-cooled three-phase motors,

- flat motors,

- three-phase motors in a flat design – speeds up to 24,000 rpm,

- explosion-proof motors (ATEX),

- Ultra Premium IE5 motors

- stainless steel motors (IP68, water-cooled),

- high-speed three-phase machines (for use on test benches),

- slip ring three-phase motors,

- circulating fan motors,

- single-phase motors,

- AC servomotors (with high torque at standstill),

- encapsulated motors (IP67, to 6kW),

- submersible motors (depth of immersion up to 30m, to IP68 standard),

- drive motors for cranes and hoists:

- with pole switching up to 2/32 poles,

- and variable speed.

Application of AC motors manufactured by Emod Motoren:

- sewage pumps,

- lifts and escalators,

- cranes,

- woodworking machinery,

- industrial ovens,

- plastic injection moulding machinery,

- food-processing machinery,

- ventilation and air-conditioning technology,

- test bench drives,

- roller conveyor drives,

- shipbuilding – drives for winches and bow thrusters,

- jet fans (version for combustion gases),

- vacuum pumps.

Based on your enquiry, we are able to offer a complete solution tailored to your needs.