The construction domain of sewage pumps, both immersion and surface types, means primarily quality, simple design, long lifespan, and maintenance-free, reducing costs of use and contributing to better environmental protection. Landustrie pumps are efficient and solid solutions, dedicated to specific tasks, and adapted to the Customer’s particular needs. These fundamental rules can be found in each and every product tested and manufactured in Sneek. Since different materials and chemicals were found in sewage, Landustrie has been offering pumps from various types of materials and with required certificates. The primary objective of Landustrie is to meet the challenges posed to pumps, which directly contributes to Customer satisfaction.

The pump selection for clean water is relatively simple, but selecting an appropriate product for contaminated water tends to be complicated. We deliver suitable pumps for projects considering several basic rules.

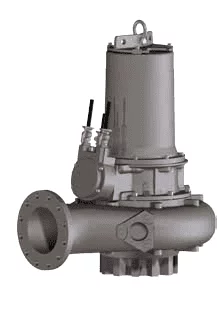

- The best efficiency and failure-free work are achieved in the case of pumps with Vortex rotors. They are used for contaminated water with a high content of solids and long fibres, which reduces accidental blocking of the impeller to a minimum.

- Closed screw pump rotors are used for more significant volumes. It is a new generation of impellers with a single-channel achieving high efficiency and sound properties, thanks to which the rotor is not blocked.

- For high volumes and low heights, we offer Archimedes screw pumps that feature anti-blocking properties combined with high efficiency and reliability.

- Pumps with grinders are used in special cases with a high concentration of solids and fibres.

Cast iron casing is appropriate for the majority of uses.

Duplex is used in the case of chemical contaminants and contaminants containing a frictional material.

NiHard4 zcomposed of the hardest components, is used in the case of contaminants containing the most significant number of frictional materials.

The selection of appropriate LANDY centrifugal pumps is achieved by analysing the composition of impurities in the presence of chemicals, friction agents, form, and size of solids. It is also essential to consider the surrounding working environment and the risk of explosion.