On August 13, 2024, MMR Group TransComfort received the National Technical Assessment [pl. KOT] of the Road and Bridge Research Institute with a positive assessment of the properties of prefabricated slabs for road surface integrated with track – MMR MONOLITH.

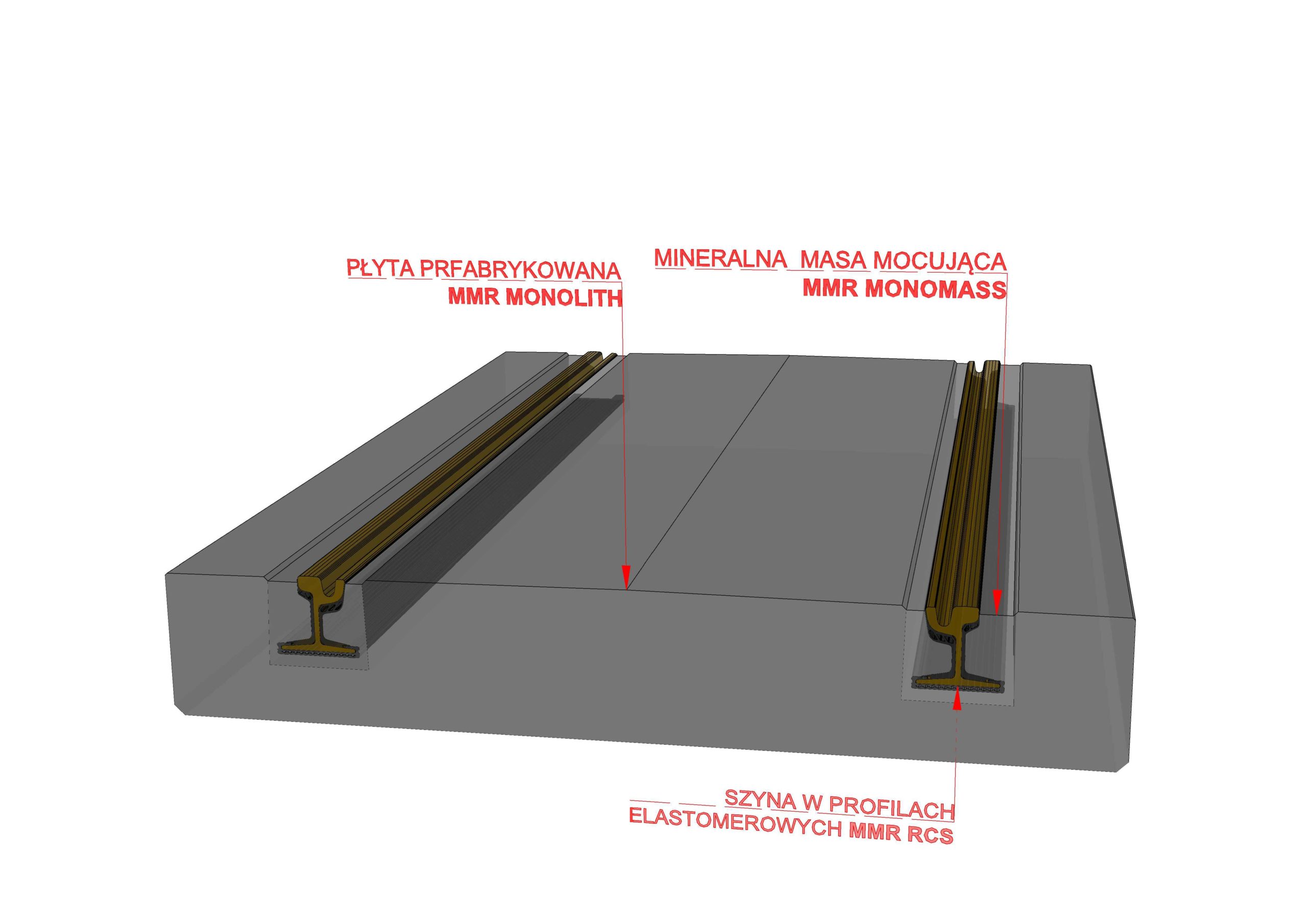

MMR MONOLITH is the final element of the complete prefabricated ballastless structure, that MMR Group TransComfort plans to implement soon. Together with the rail fastening system with elastomeric profiles MMR RCS, and the mineral fixing grout in the rail channels MMR MONOMASS, the prefabricated plate system forms a durable rail-road structure capable of withstanding loads both along and across the tracks. Standardization, high quality, and a small number of components make this structure easy to implement, and thanks to the fast-setting grout, it can bear loads as soon as 18 hours after rail installation.

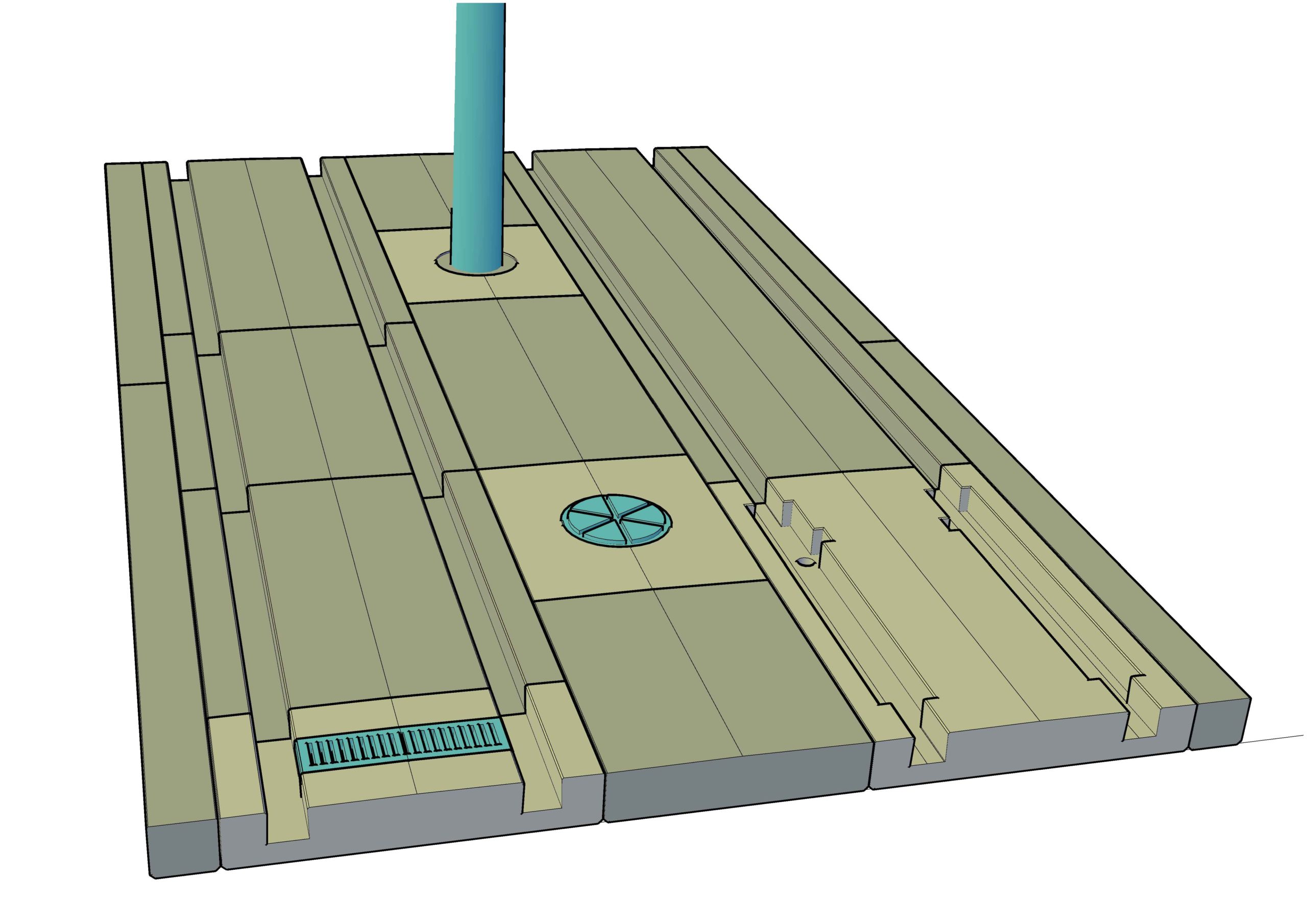

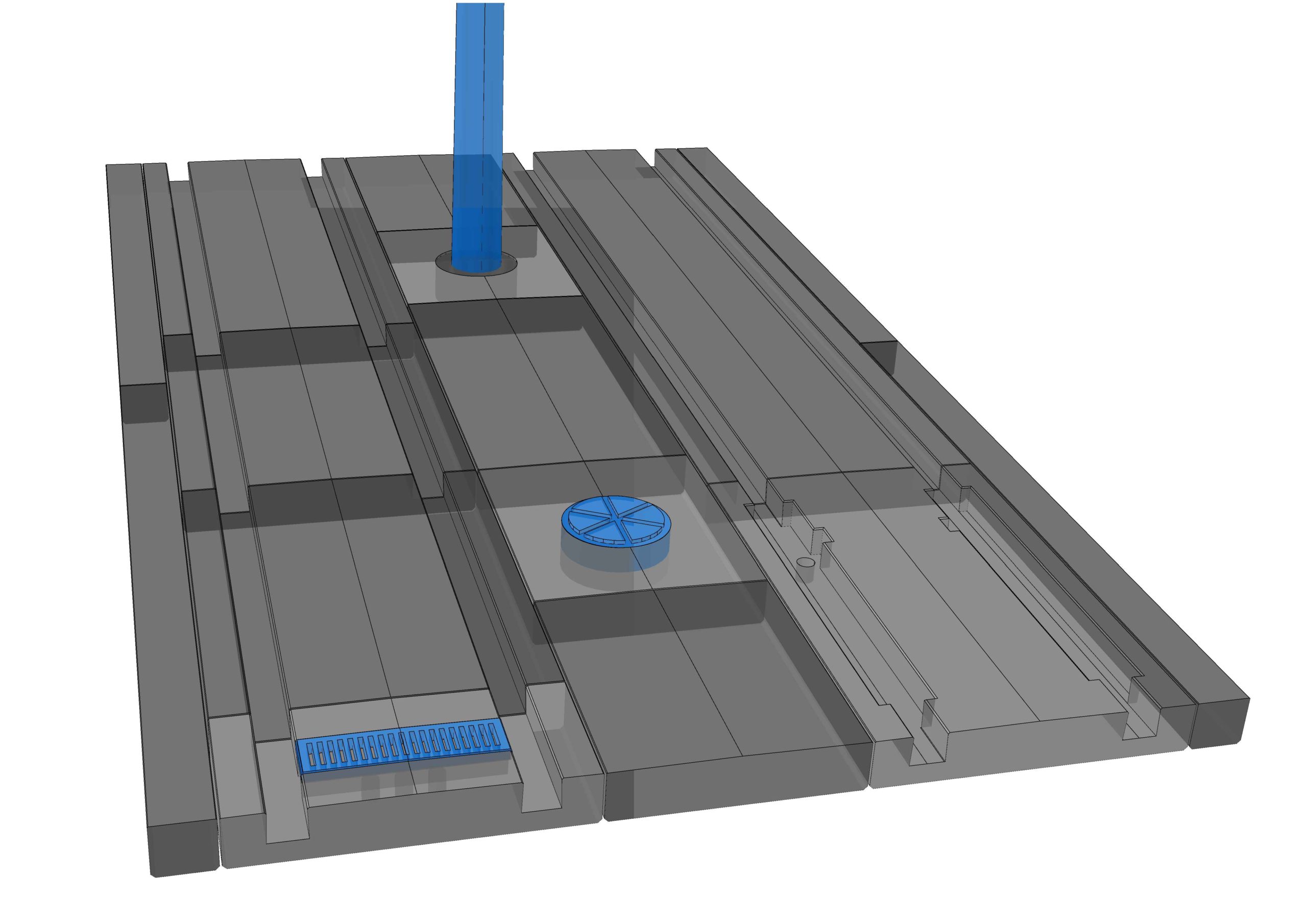

MMR Group TransComfort introduces the following types of plates in the system:

• track plate,

• full intertrack plate,

• intertrack plate with openings for fittings, traction poles, and streetlights,

• side plate,

• drainage plate,

• cable plate,

• plate for track alignment devices,

• switch plate.

The plates will be available in lengths ranging from 0.5 to 12.0 meters, with interchangeable modules every 100 mm. The track plates are designed for track widths of 1000 mm and 1435 mm, and for any rail profile. A key advantage of the MMR MONOLITH prefabricated plate set is its innovative construction solutions and fast installation technology.

Contact:

Mariusz Zaremba

Deputy Sales Director, Railway Vehicles OE Infrastructure

mariusz.zaremba@mmrgroup.pl

![Delivery of 18,000 meters of CuMg 0.4 (BZ II) wire for Tramwaje Warszawskie [Warsaw Trams]](https://tc.mmrgroup.pl/wp-content/uploads/2025/07/Sygnet-MMR-Group-TC.png)